MP35N Shoulder Bolts

MP35N Shoulder Bolts

MP35N shoulder bolts are known for their extraordinary strength and are the strongest bolts we offer at Extreme Bolt. MP35N bolts owe their extraordinary strength to a unique alloy combination of nickel, cobalt, chrome and molybdenum and have ultimate tensile strengths that range from 227 ksi to 294 ksi (with age hardening).

Beyond the strength of MP35N shoulder bolts, they are also exhibit good corrosion resistance and can resist most mineral acids, hydrogen sulfide, seawater and salt spray environments.

MP35N bolts are also resistant to high temperature oxidation and could operate in environments up to 800°F and still maintain much of its strength.

One of the highest strength alloys available to industry

· Extreme high strength properties up to 300 ksi ultimate tensile.

· Good in moderately elevated temperatures of 800°F.

· Moderate corrosion resistance.

· MP35N chemisty, specs, and heat treatments

· Datasheet for MP35N

· MP35N shoulder bolt features and benefits

Applications where MP35N shoulder bolts are often found are: aerospace, defense, marine, chemical processing, oil and gas and medical.

Resources: MP35N Torque Spec

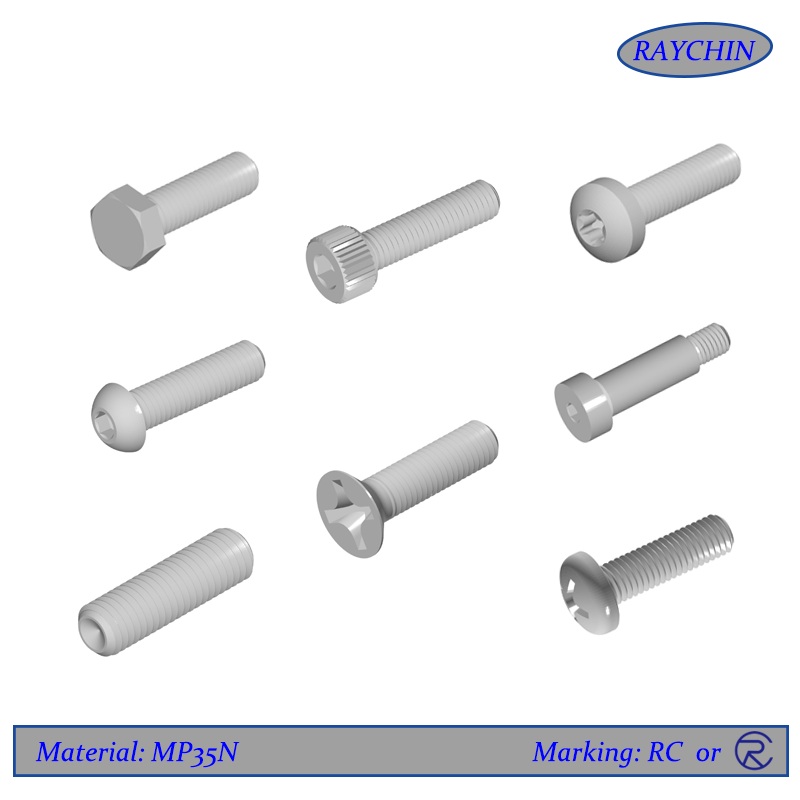

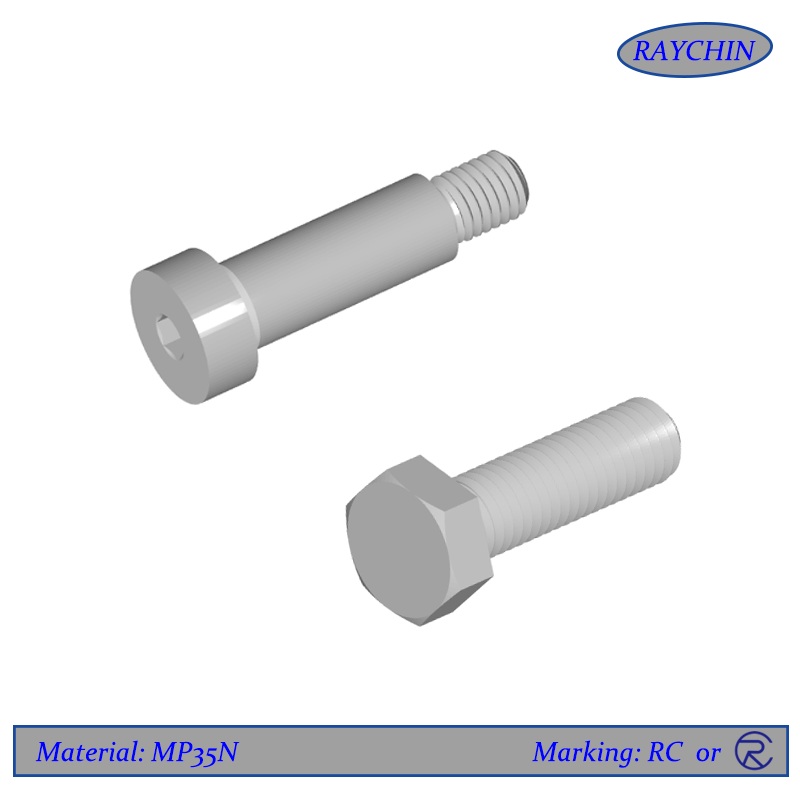

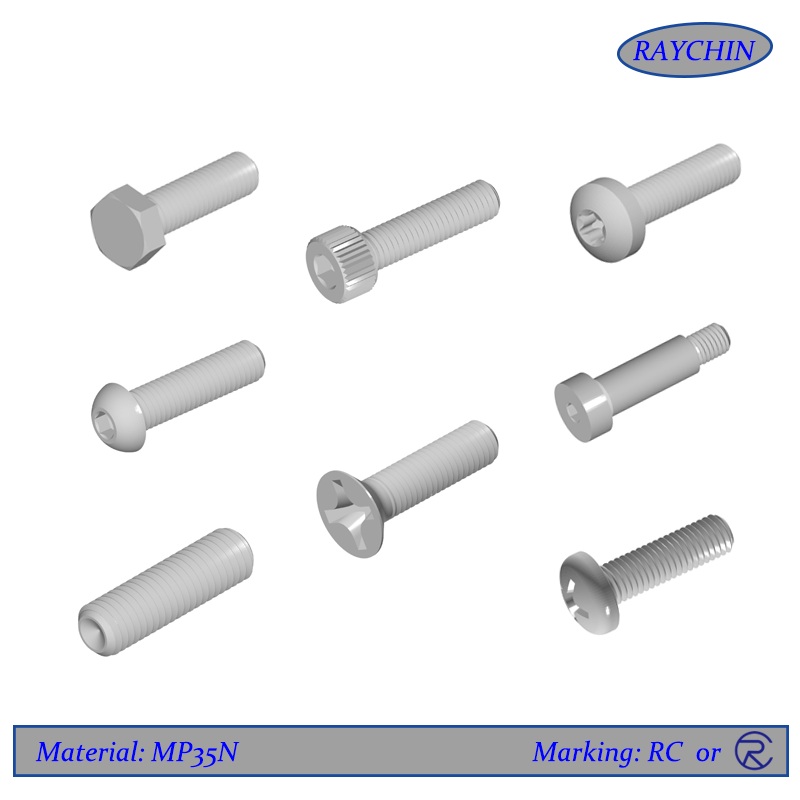

Bolt Types Available: Hex Bolts, Shoulder Bolts

MP35N Shoulder Bolt Features and Benefits

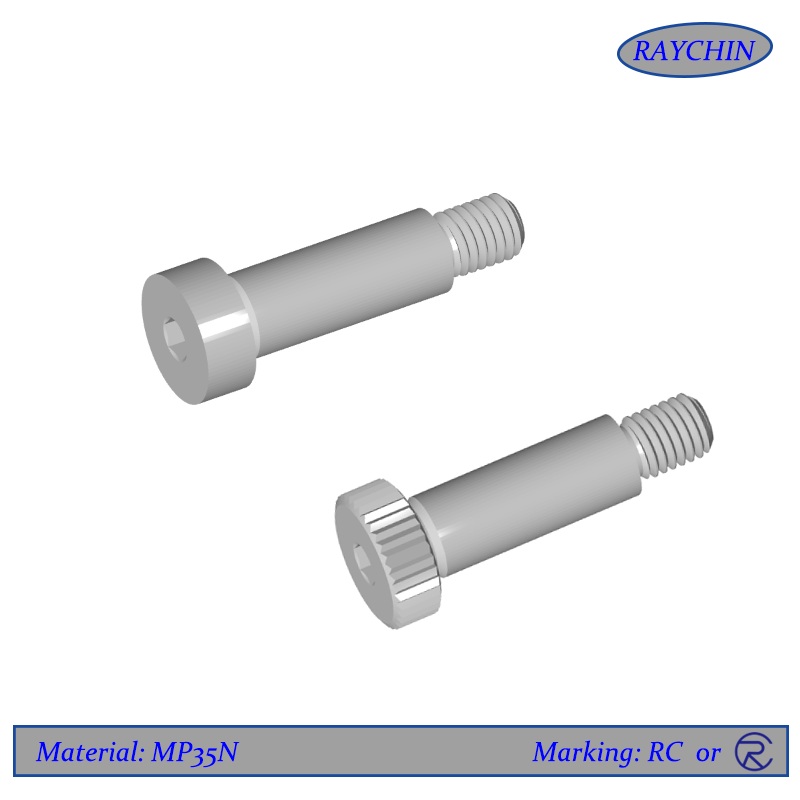

MP35N shoulder bolts, also called stripper bolts are a unique fastener with three main parts: head, shoulder, and thread. The head has the largest diameter and is where the torque is applied, typically with a socket driver. The shoulder is smooth and unthreaded, and has a set diameter and length. The shoulder’s role is to act as a shaft or dowel for rotating parts, axles for rolling parts, guides for sliding elements, and pivot points. The final part of a MP35N shoulder bolt is the threaded shaft. The threaded portion of a shoulder bolt has a major diameter slightly smaller than the shoulder diameter.

MP35N Chemistry, Spec and Heat Treatments

Heat Treating & Aging: MP35N is usually supplied in heat treated and cold drawn condition AMS 5844. In this state the MP35N can be worked into the desired fastener form and aged to the AMS 5845 specification. Once aged, the MP35N material could achieve it full strength potential.

MP35N Specifications: AMS 5844, AMS 5845, AMS7468, ASTM F562, NACE MR0175

MP35M | Ni | Co | Cr | Mo |

Typical% | 35 | 35 | 20 | 10 |

MP35N Mechanical Data (Dependent of Part Size)

Guaranteed Minimum Properties | Nominal Properties |

| USt(%) | Yield Strength (0.2%) ksi | Elongation (%4D) | RA(%)) | HRC | UTS(kis) | Yield Strength (0.2%) ksi | Elongation (%40) | RA(%) | HRC |

MP35N Cold Dg Full Strength | 260 | 230 | 8 | 35 | 44 min | 285 | 275 | 9 | 45 | 50 |

MP35N Corrosion Data

Media | Corrosion Resistance | Media | Corrosion Resistance |

Nitric Acid | Good | Sulfuric Acid | Good |

Phosphoric Acid | Good | Acetic Acid | Excellent |

Sodium Hydroxide | Good | Salt Spray (NaCl) | Excellent |

Sea Water | Excellent | SourOil/Gas | Excellent |