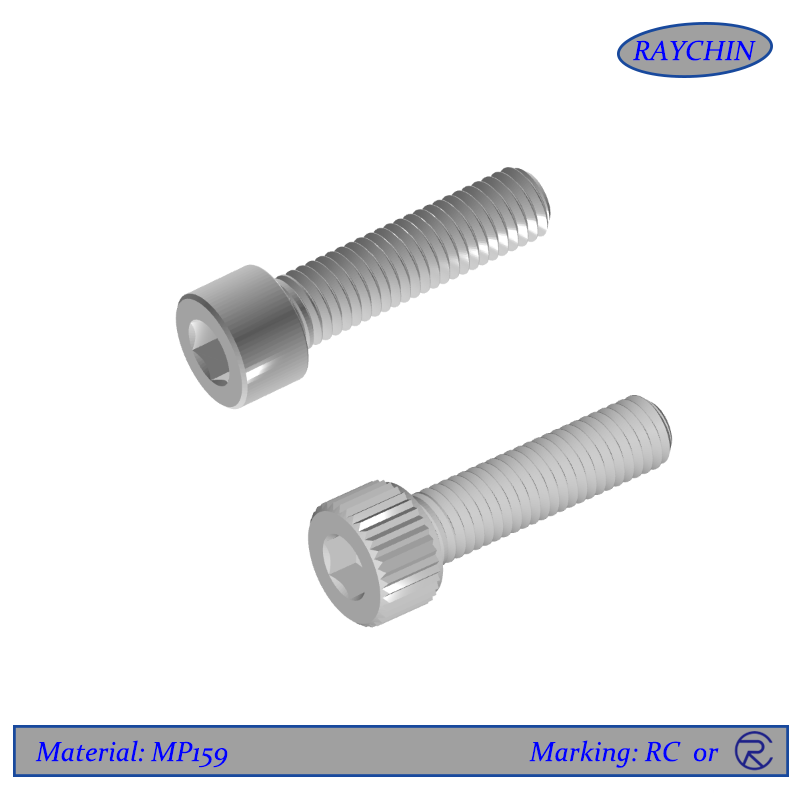

MP159 Socket Head Cap Screws

Brand RAYCHIN

Product origin China

Delivery time 5-35 DAYS

As aerospace engineering advances, so must the materials to meet the technological requirements of this industry. Screws made from MP159 have been developed to provide a solution to high temperature, high strength components. MP159 socket head cap screws offer strength capabilities similar to other Cobalt Alloys (MP35N) but can be used at much higher temperatures - up to 1100°F, compared to MP35N’s usable limit of 800F. In addition, MP159 screws can be used beyond 1100°F in short term situations.

MP159 Socket Head Cap Screw

As aerospace engineering advances, so must the materials to meet the technological requirements of this industry. Screws made from MP159 have been developed to provide a solution to high temperature, high strength components. MP159 socket head cap screws offer strength capabilities similar to other Cobalt Alloys (MP35N) but can be used at much higher temperatures - up to 1100°F, compared to MP35N’s usable limit of 800F. In addition, MP159 screws can be used beyond 1100°F in short term situations.

Ultra-strength combined with extreme temperature capabilities

· Extreme high strength properties up to 275 ksi ultimate tensile.

· Maintains superior strength to 1100°F.

· MP159 chemisty and specification

· Datasheet for MP159

· MP159 socket head cap screw features & benefits

Key Benefits

· High ultimate tensile strength of 275 ksi and yield strength of 265 ksi (Cold Worked and Age Hardened) combined with excellent ductility and toughness

· Similar corrosion resistance compared to MP35N which is usable in mineral acids, hydrogen sulfide, seawater and salt spray environments.

· Excellent fatigue resistance and creep strength at elevated temperatures

· Excellent resistance to crevice corrosion, stress corrosion cracking and hydrogen embrittlement

Applications

· The aerospace industry relies on MP159 screws for its most advanced gas turbine and jet engines, rocket boosters and jet propulsion systems.

· Power generation and chemical processing utilize MP159 socket head cap screws for applications that demand high strength at extreme temperatures.

Resources: MP159 Torque Spec

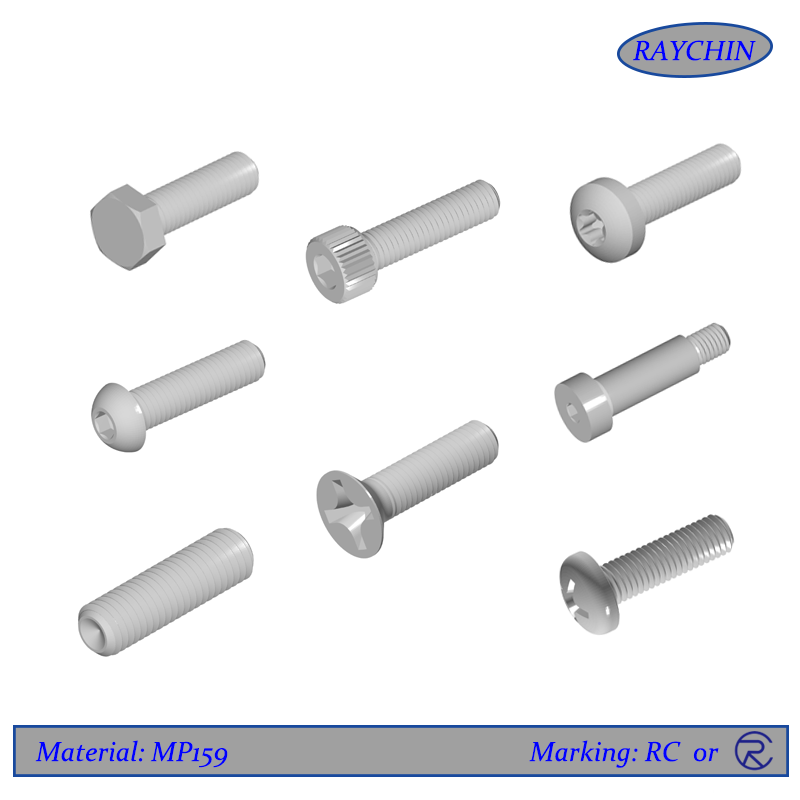

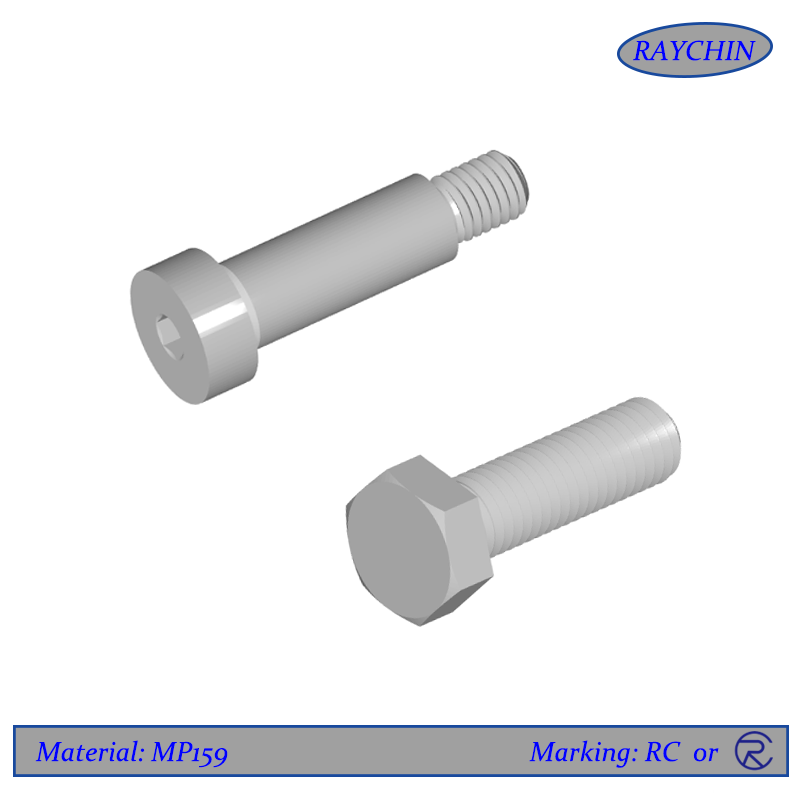

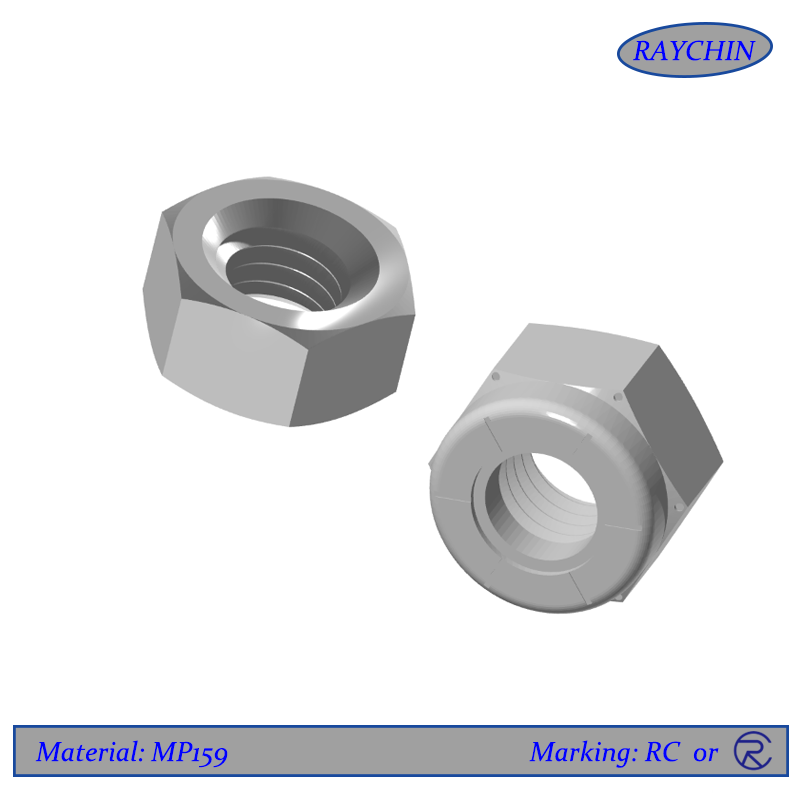

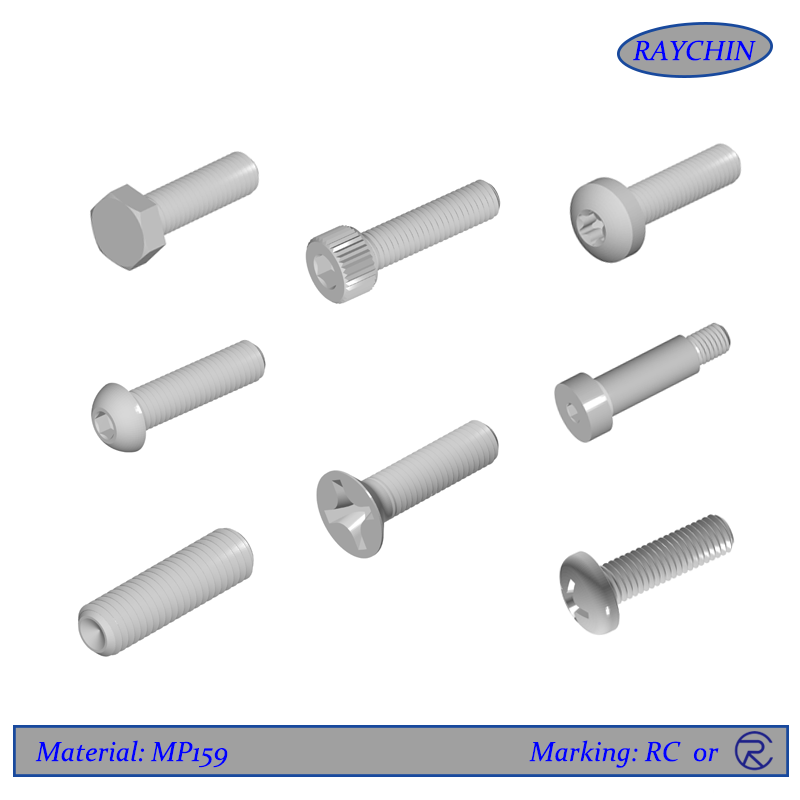

MP159 Screw Types: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Cap Screws, Hex Cap Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws

MP159 Socket Head Cap Screw Features and Benefits

When it comes to MP159 socket head cap screws, it’s all about clearance. These screws are the best choice for applications with limited installation access or clearance. Yet if you have an application with a lot of debris, you may want to select a MP159 hex head bolt or hex head cap screw, as they don’t have a socket drive which could get clogged.

Advantages:

• Ideal for applications with limited access as they require very little clearance around the fastener.

• Socket head cap screws can be used in locations where externally wrenched fasteners aren't desirable.

• Weight reduction on application as MP159 socket head cap screws are smaller – being that the cylindrical heads of socket screws need less space than hex heads and require no additional wrench space.

• Also known for safety, reliability and economy.

MP159 Chemistry and Specifications

MP159N Specifications: UNS R30159

MP159 | Co | Ni | Cr | Fe | Mo | Ti | Nb | Al |

Typical% | 35.7 | 25.5 | 19 | 9 | 7 | 3 | 0.6 | 0.2 |

MP159 High Strength Data

Cold Worked, 48% +1225eF (663eC)/4 hrs/AC | |

UTSksi(MPa) | 275(1895) |

Yield strength at 0.2% ksi (MPa) | 265(1825) |

% Elogation | 8 |

%RA | 35 |

Shear strength ksi (MPa) Per MIL- STD-1312 | 138(951) |