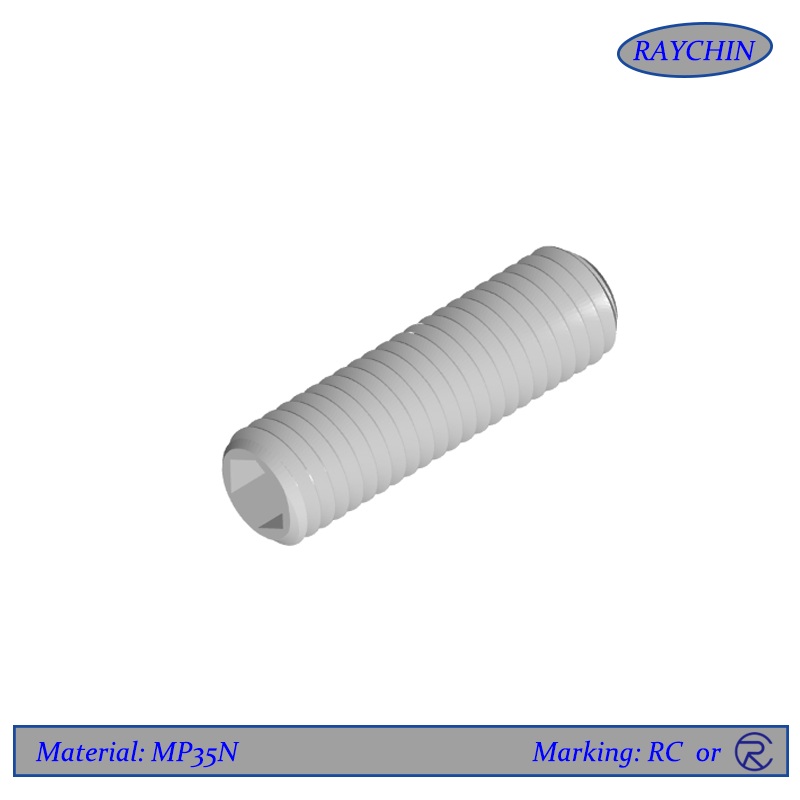

MP35N Set Screws

MP35N Set Screw

MP35N set screws are known for their extraordinary strength and are the strongest screws we offer at RAYCHIN. MP35N screws owe their extraordinary strength to a unique alloy combination of nickel, cobalt, chrome and molybdenum and have ultimate tensile strengths that range from 227 ksi to 294 ksi (with age hardening).

Beyond the strength of MP35N set screws, they are also exhibit good corrosion resistance and can resist most mineral acids, hydrogen sulfide, seawater and salt spray environments.

MP35N screws are also resistant to high temperature oxidation and could operate in environments up to 800°F and still maintain much of its strength.

One of the highest strength alloys available to industry

· Extreme high strength properties up to 300 ksi ultimate tensile.

· Good in moderately elevated temperatures of 800°F.

· Moderate corrosion resistance.

· MP35N Chemistry, specs, and heat treatments

· Datasheet for MP35N

· MP35N set screw features and benefits

Applications where MP35N set screws are often found are: aerospace, defense, marine, chemical processing, oil and gas and medical.

Resources: MP35N Torque Spec

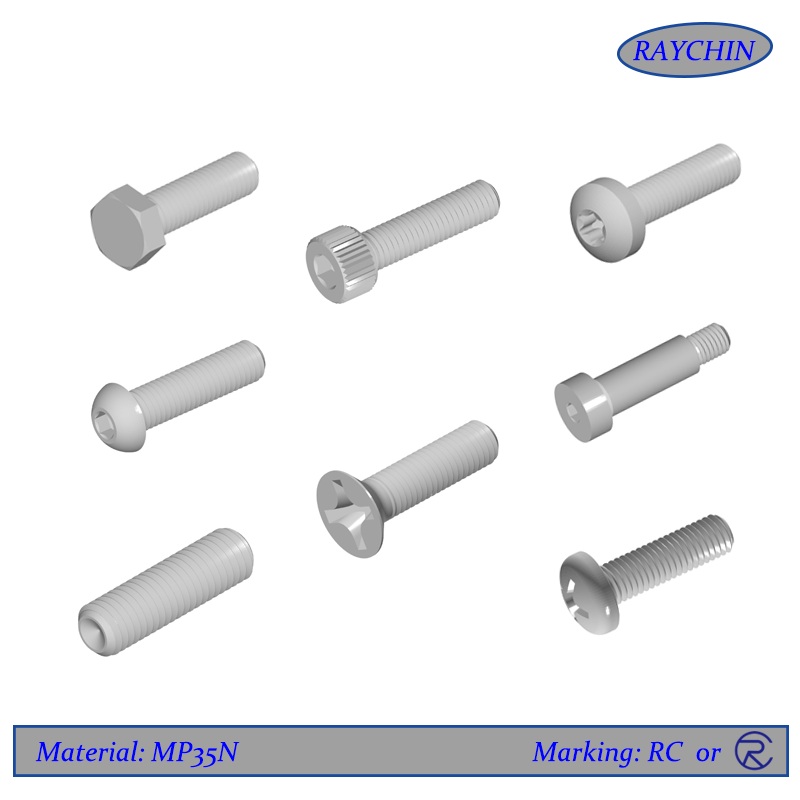

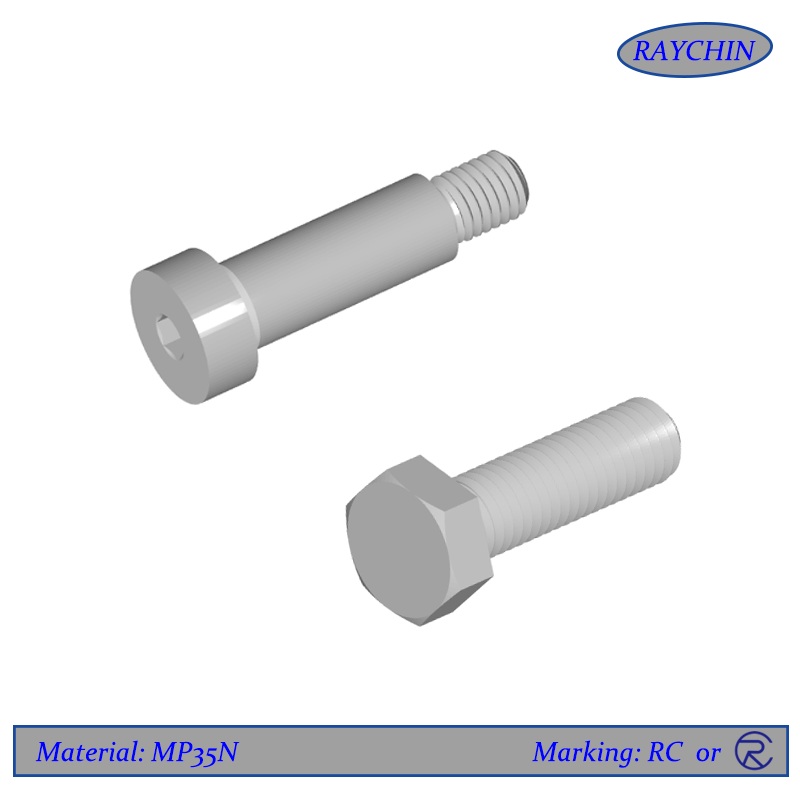

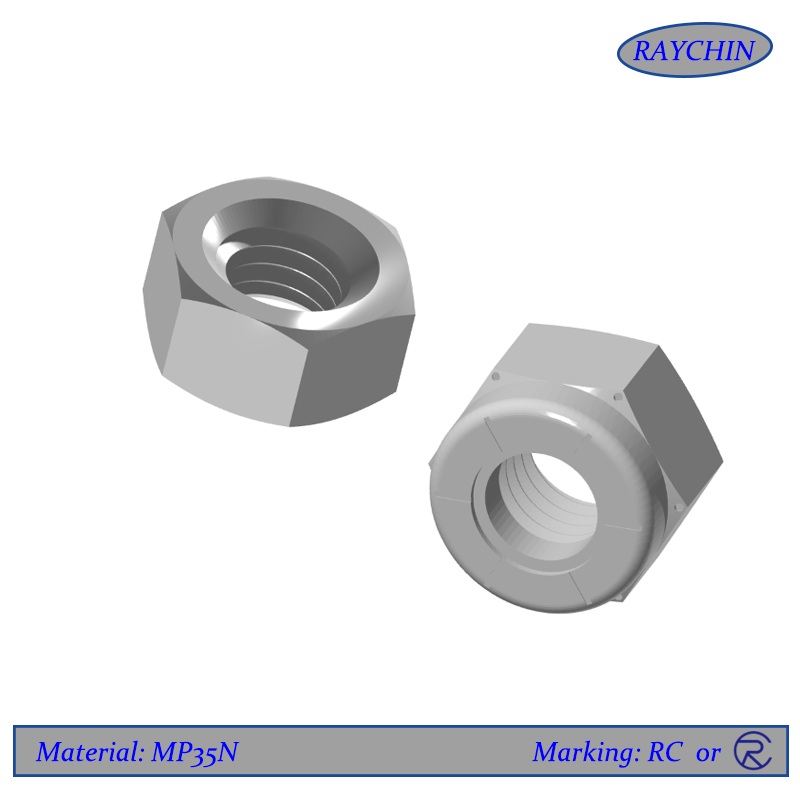

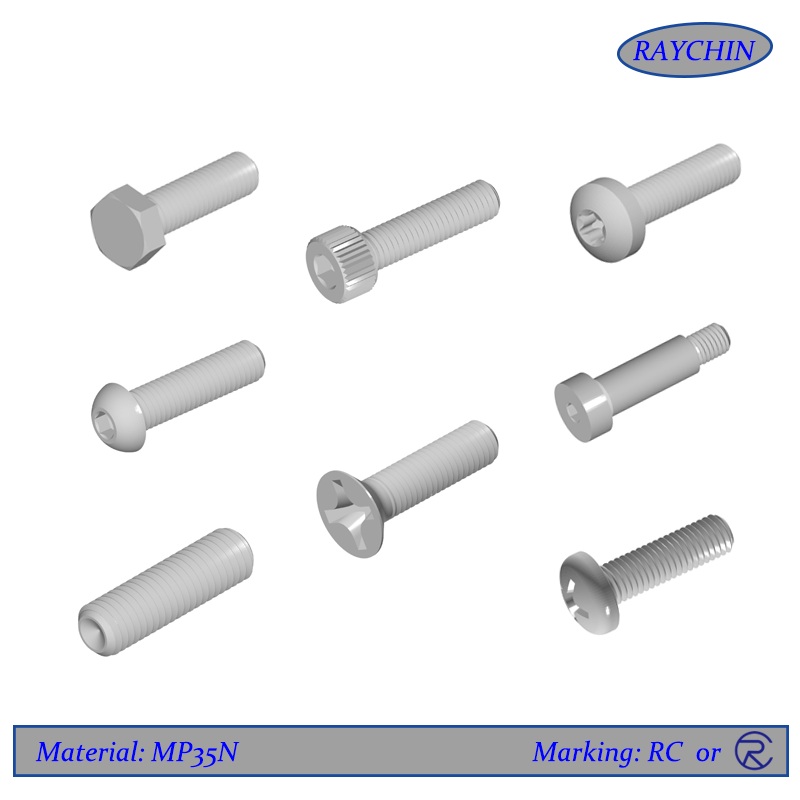

Screw Types: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws, Torx Screws

MP35N Set Screw Features & Benefits

MP35N set screws are unique in that they have no screw head, meaning that they have no protruding part past the threaded shaft. They are thread only and are available with a socket or slotted driver insert at one end. Set screws are used to secure an object within or against another object. Typically they secure a rotating part such as a gear or shaft. MP35N set screws are driven through a threaded hole in the rotating part until it is tight against the inner object, preventing from moving relative to the outer object. Set screws are available with various points depending on the application.

Cup Point

This is the most commonly used set screw and is identified by a cup-shaped indentation on one end. MP35N cup points are typically used for a quick, semi-permanent or permanent applications where it is acceptable to cut the cup point edge of the screw.

Cone Point

A cone point is easily identifiable by its sharp cone-shaped point – just like an ice cream cone. MP35N cone point set screws deliver the strongest clamping force due to the deep penetration of the point. As a result they are used for permanent assembly.

Flat Point

Flat Point

The cheapest and simplest of the set screw point styles, this screw has a flat surface on the bottom of the screw. This type is used when you need the ability to frequently change parts and require minimal shaft deformation.

MP35N Chemistry, Specs and Heat Treatments

Heat Treating & Aging: MP35N is usually supplied in heat treated and cold drawn condition AMS 5844. In this state the MP35N can be worked into the desired fastener form and aged to the AMS 5845 specification. Once aged, the MP35N material could achieve it full strength potential.

MP35N Specifications: AMS 5844, AMS 5845, AMS7468, ASTM F562, NACE MR0175

MP35M | Ni | Co | Cr | Mo |

Typical% | 35 | 35 | 20 | 10 |

MP35N Mechanical Data (Dependent of Part Size)

Guaranteed Minimum Properties | Nominal Properties |

| USt(%) | Yield Strength (0.2%) ksi | Elongation (%4D) | RA(%)) | HRC | UTS(kis) | Yield Strength (0.2%) ksi | Elongation (%40) | RA(%) | HRC |

MP35N Cold Dg Full Strength | 260 | 230 | 8 | 35 | 44 min | 285 | 275 | 9 | 45 | 50 |

MP35N Corrosion Data

Media | Corrosion Resistance | Media | Corrosion Resistance |

Nitric Acid | Good | Sulfuric Acid | Good |

Phosphoric Acid | Good | Acetic Acid | Excellent |

Sodium Hydroxide | Good | Salt Spray (NaCl) | Excellent |

Sea Water | Excellent | SourOil/Gas | Excellent |